Admissions open for classroom and online training. ENROLL NOW.

Mechanical Design Domain Engineer (MDDE) Program

With 100% Placement Assistance!

Launch Your Career in Mechanical Design with IFS Academy

New batch starts from 3rd & 24th June, 2024

Program Overview

IFS Academy, in collaboration with a leading Engineering Services company, proudly offers the Mechanical Design Domain Engineer (MDDE) Program. Tailored to meet industry job requirements, this program ensures that fresh mechanical engineers are well-equipped to secure positions in the industry upon completion. The curriculum has been meticulously designed by industry veterans with over 20 years of experience, ensuring that students receive the highest quality education and training.

Have Any Doubts About the Course? Talk With Our Career Counselor.

Why Choose the MDDE Program?

-

Industry-Aligned Curriculum: Designed by experts with extensive industry experience to meet current job market demands.

-

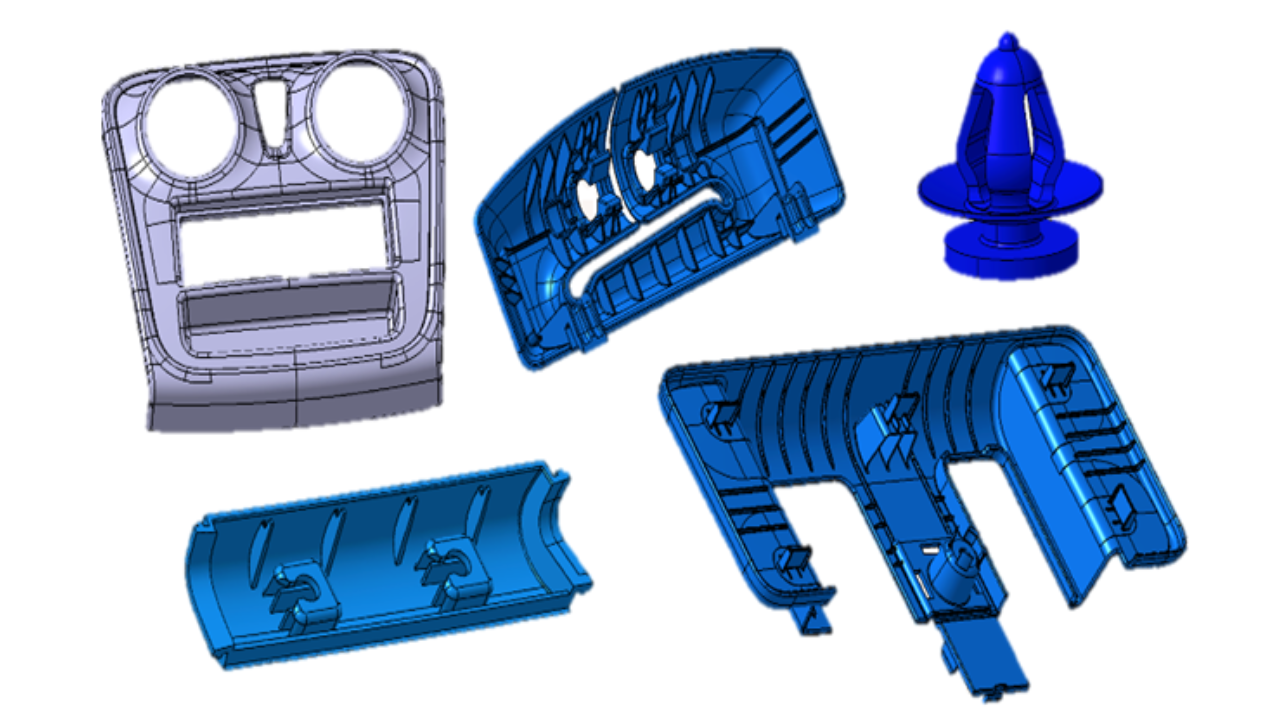

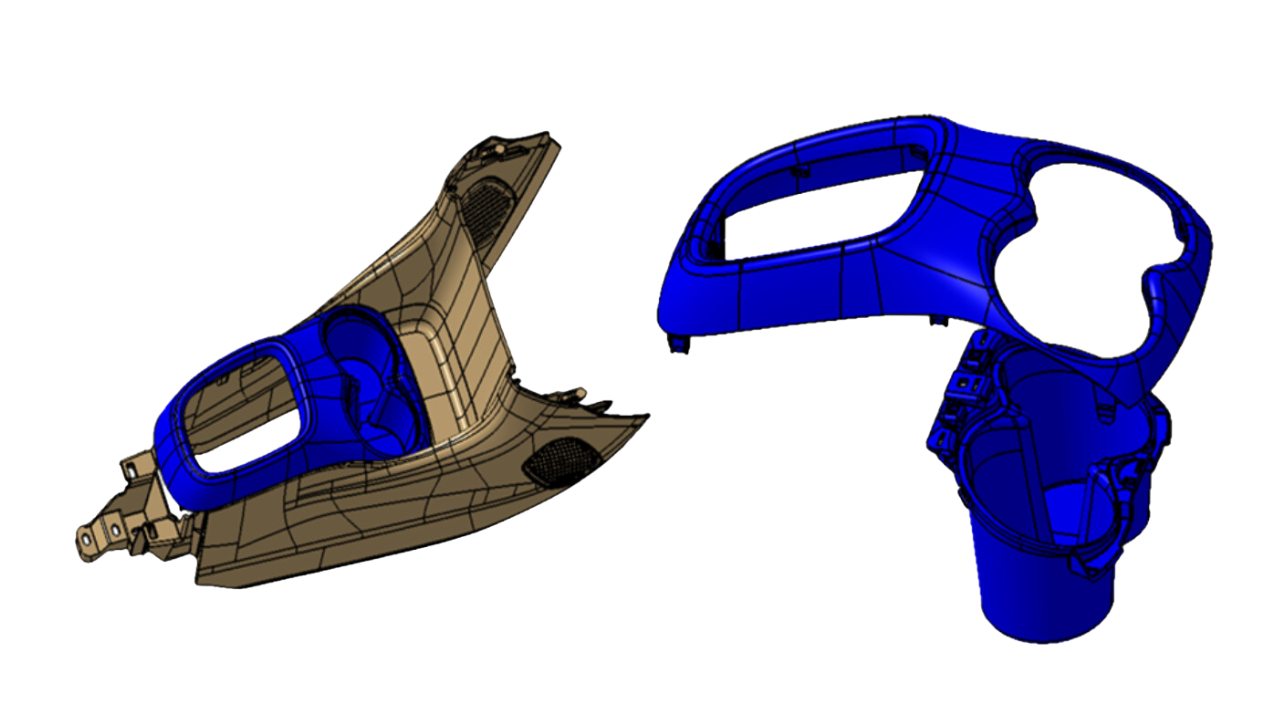

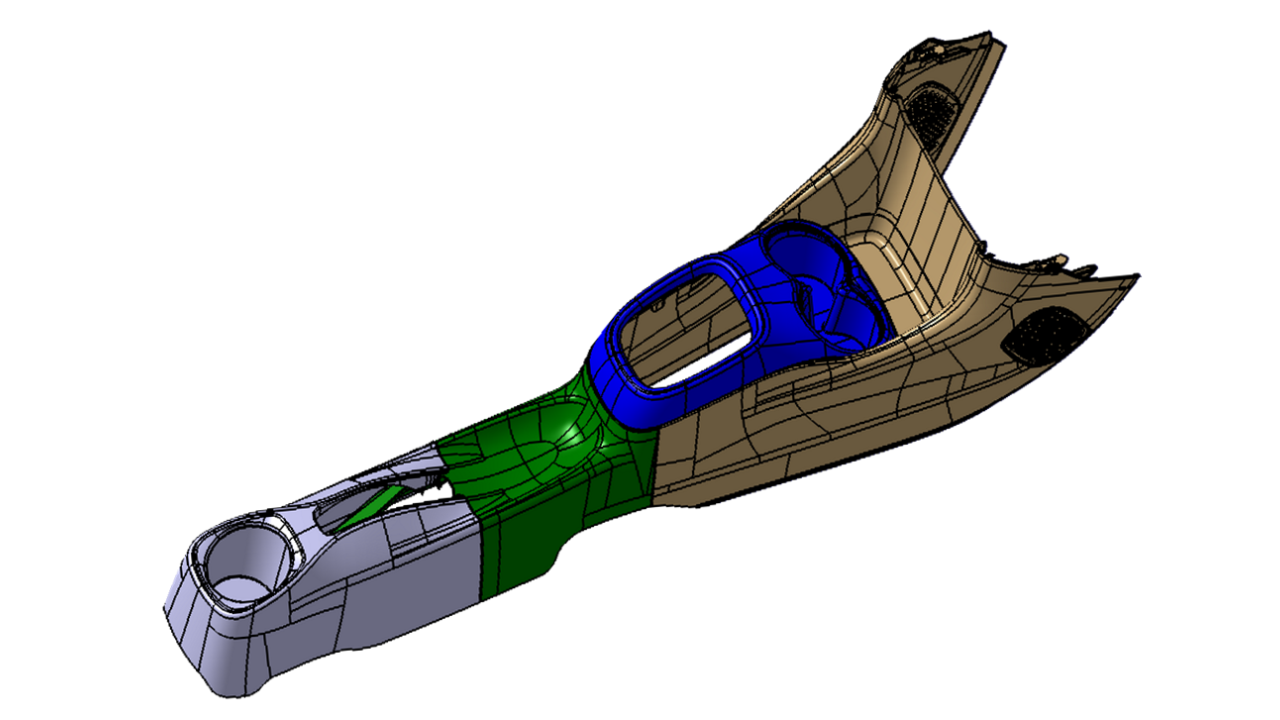

Hands-On Software Training: Gain proficiency in essential software tools such as CATIA, NX CAD, and SolidWorks.

-

Comprehensive Domain Coverage: Learn about Plastic Design, CAD Execution, Sheet Metal Design, GD&T, Tolerance Stack-Up Analysis, NPD/NPI Process, DFMEA (AIAG), PPAP (AIAG), and Engineering Fundamentals.

Program Highlights

-

Expert Instructors: Learn from industry professionals with 20+ years of experience.

-

Placement Assistance: Our dedicated Training & Placement team will guide and support you through the campus placement process.

-

Certified Training: Receive an IFS Academy certified course completion certificate upon successful completion.

-

Authorized Curriculum: As an Autodesk and SIEMENS PLM Software Authorized Educational Partner, we offer an up-to-date curriculum in line with the latest software versions.

-

Flexible Learning: Participate in Instructor-Led Online Live Training sessions for a convenient and interactive learning experience.

Key Features:

-

Rigorous curriculum covering CAD tools such as CATIA V5, SolidWorks & NX CAD.

-

Industry-oriented training encompassing Plastic Design, Sheetmetal Design, NPD/NPI Process, and more.

-

In-depth sessions led by experts with a collective experience of 35+ years.

-

Flexible online training with mentor support for doubt clarification.

-

Practical learning through industry projects and assignments.

-

Certification upon meeting evaluation criteria.

-

Assistance in resume building, interview preparation, and mock interviews.

-

100% placement assistance for successful candidates.

Faculty Profiles:

Faculty 1:

-

Over 21 years of global experience in design & development industries.

-

Holds 8+ granted patents in the USA & Europe.

-

Certified in ASME – GDTP and "Associate Value Specialist (VAVE)".

-

Mentored over 7500 Design Engineers globally.

Faculty 2:

-

Holds BE (Mechanical) + ME (Masters) in Thermal Engineering.

-

Recognized Plastic Design Expert with experience in global brands.

-

Mentor for design engineers in various industries.

-

Published technical papers on Nano Technology.

Download the Syllabus To View the Whole Course Outline and Learning Objectives.

Course Outline:

Plastic Design Domain

-

Introduction to plastic

-

Plastic properties

-

Plastic Moulding processes

-

Introduction to injection Moulding tool

-

Sliders and lifters

-

Plastic defects

-

Plastic post processes

-

Plastic joining methods

-

Class A surface & surface continuity

-

Design guidelines of plastic part and features

-

Structural design of plastic

-

Moldflow analysis

-

Design for manufacturing and assembly (DFMA)

Cad execution:

-

A to B conversion

-

Close volume creation with master section

-

Creation of skin foam

-

Remastering/ Reverse engineering

-

Design of plastic features

Projects:

-

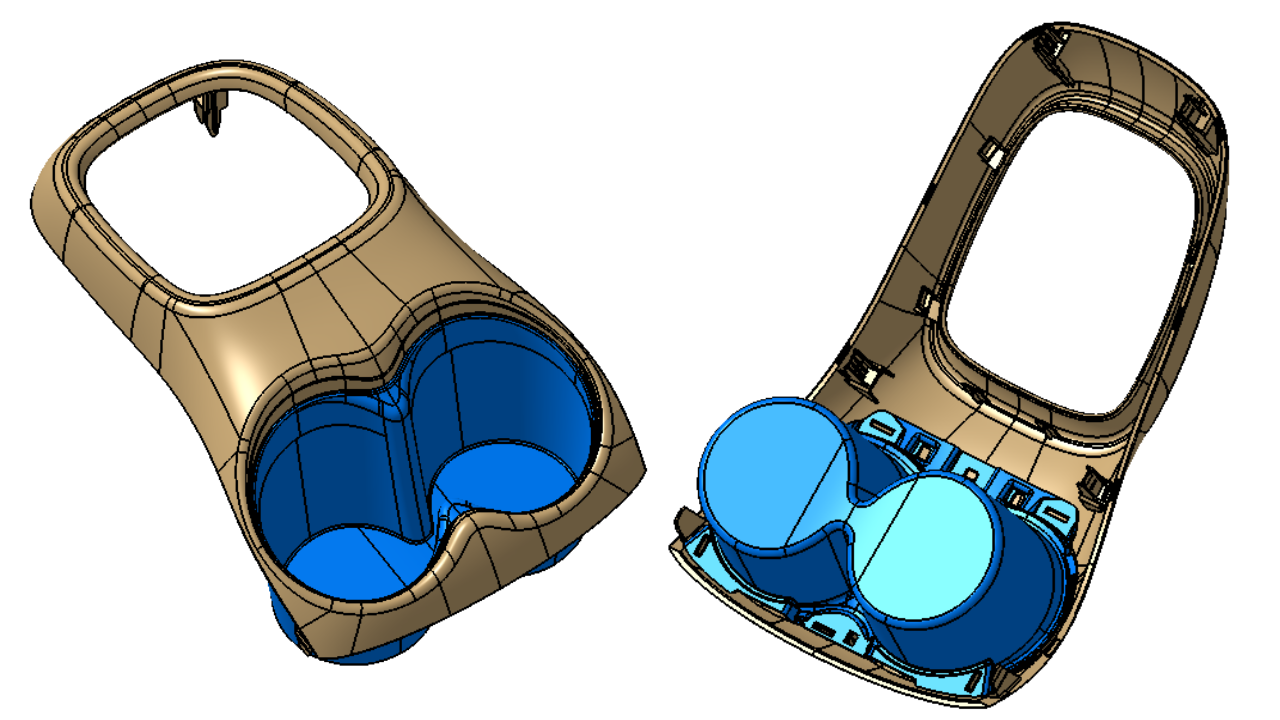

Automotive: Door trim, center console, headliner, map pocket, arm rest, airbag cover

-

Home Appliances: Refrigerator container, electronic console, egg tray

-

electronics: Enclosure of Wi-Fi router, PCB enclosure

-

Medical: Thermal gun, BP monitoring machine enclosure

Sheetmetal Design Domain

-

Introduction to Sheetmetal

-

Material Selection

-

The shearing processes

-

The Press-Brake Operations

-

The stamping operations

-

The Roll Forming Operations

-

The Spinning Operation

-

The Drill Press Work

-

The Deburring & Abrasion

-

The Joining Operations

-

The Heat Treatment Operations

-

Plating & Painting

-

Sheetmetal design projects

GD&T (Basic & Pro)

-

Introduction to GD&T

-

GD&T – Rules, Definitions and Terms

-

GD&T - Modifiers

-

Form Control

-

Planer & Non-Planer Datums

-

Orientation Control

-

Location Controls

-

Profile Control

-

10+ Case Studies

Tolerance Stack-up Analysis (WC | RSS | MRSS Methods)

-

Approaches to finalize tolerance values of dimensions

-

Engineering Fits

-

Part and Assembly Stack-up analysis

-

Tolerance stack-up with GD&T applications

-

Worst case and stastical analysis

-

Process capability analysis (Cp, Cpk)

-

20+ Case Studies

NPD | NPI Process

-

Phases of NPD | NPI Process

-

Opportunity Exploration and Target Setting

-

Brainstorming and Concept Selection

-

Concept Feasibility

-

Design Release

-

Process Development

-

Product & Process Validation

-

Lessons Learned

-

Systematic Problem Solving - RCA, A3 and 8D

-

Patent Process

-

Value Engineering

Register Now & Get Discount. Only Limited Seats Available. Grab The Offer Now.

DFMEA (AIAG)

-

Failure Mode Avoidance (FMA)

-

Pre-DFMEA Tools

-

Boundary Diagram

-

Interface Matrix

-

Product Structure Tree (PST)

-

Function Tree (FT)

-

Fault Tree Analysis (FTA)

-

Parametric Diagram

-

RCL

-

IFRL

-

DFMA form as per AIAG manual

-

Design verification plan (DVP)

PPAP (AIAG)

-

Study of 18 documents and records of PPAP

Revisit of Engineering concepts for interview

-

Strength of material

-

Fluid mechanics

-

Thermodynamics

-

Engineering drawing

-

Heat transfer

-

Manufacturing

Software Tools Covered:

-

CATIA V5

-

SolidWorks

-

NX CAD

Course Duration:

| Sr. No. | Course Title | Duration (Hrs.) | Syllabus |

|---|---|---|---|

| 1 | (MDDE) Mechanical Design Domain Engineer Course Curriculum | 6 Months | Download |

Who Can Enroll?

-

BE Mechanical/Automobile Third Year and Final Year Students

-

Fresh Graduates in Mechanical/Automobile Engineering

Enrollment Requirement:

Pass the eligibility assessment test.

Take the Eligibility Assessment Test:

https://www.classmarker.com/online-test/start/?quiz=ygh664de34220b9e

Course Schedule:

Daily 3 hrs. Class (Monday to Friday)

Internship / Placement Opportunities:

Internship and placement opportunities provided upon successful course completion.

Enquire Now:

Take the first step towards a successful career in the Mechanical Design Domain. Enquire now to get detailed course information, appear for the eligibility test, and secure your place in the program.