Admissions open for classroom and online training. ENROLL NOW.

Computer Aided Manufacturing (CAM) using Mastercam Online Training

Instructor-Led Online Training

Computer Aided Manufacturing (CAM) using Mastercam Modules:

A. Mastercam for Turning (CNC – Lathe)

B. Mastercam for 3 Axis Milling (VMC)

C. Mastercam for 5 Axis (Multi-axis – Machining)

Duration: Module A: 2 Days (12 Hrs)

Module B: 4 Days (24 Hrs)

Module C: 3 Days (18 Hrs)

Schedule:Multiple Batches available in January, February & March, 2021.

Mode of Training: Instructor-Led Online Training

Have Any Doubts About the Course? Talk With Our Career Counselor.

Course Objective

The use of (CAM) Mastercam Entry Lathe, 3 Axis Milling and Multiaxis Modules for Manufacturing in various Industrial Applications.

About Mastercam Software

Mastercam, Design and Manufacturing software of CNC Software, Inc. from USA is an industry leader for more than 35 years, CNC Software takes pride in meeting the demanding needs of customers by providing excellent products at affordable prices. We adhere to our strategy of combining superior software programming with practical shop floor experience. We have remained at the forefront of CAD/CAM technology by listening to our customers’ needs, being accessible, and most of all, being dedicated to our customers. CNC Software has provided CAD/CAM solutions to more than 250,000 installations worldwide in the moldmaking, automotive, aerospace, and consumer industries.

Course Description

User can able to perform various types of analysis In order to evaluate Part & Mold. It will help user to convince the customer for the betterment of design.

Course Contents

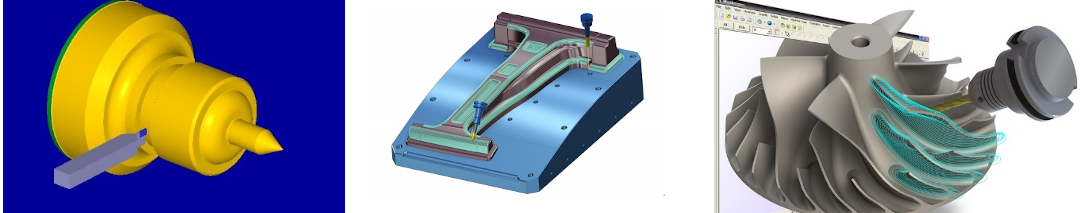

The Course Mastercam – Entry Lathe covers the Design and Set-up of Lathe/Turning environment. The Mastercam course content involves the various stages of Manufacturing a cylindrical component from concept to realisation or a manufactured end product from Machine.

The Course Mastercam – 3 Axis Milling covers the Design and Set-up of Milling environment. The Mastercam course content involves the various stages of Manufacturing a component or die, mould from Design/Concept to realisation or a manufactured end product from Machine.

The Course Mastercam – Multiaxis covers the Design and Set-up of 5 Axis

Machining environment. The course content involves the various stages of Manufacturing a complex component with undercuts from concept to realisation or a manufactured end product from Machine.

Download the Syllabus To View the Whole Course Outline and Learning Objectives.

Course Outcome

The User will be able to generate the Toolpaths for Turning operations, such Turning, Facing, Grooving etc for Lathe set-up.

The User will be able to generate the 2D and 3D Toolpaths for various industrial applications using Mastercam – Mill3D Module.

The User will be able to generate the Toolpaths for 5 Axis Machining

Course Contents

Mastercam for Turning (CNC – Lathe):-

Design functionalities:

-

2D Design

-

3D Modelling functionalities

-

Process to import 3rd Party CAD Models

CAM Functionalities:

-

Setting up Raw Material for the given Model

-

Setting up Lathe Environment as per Machine Orientation.

-

UCS

-

Selection of Cutting Tools for;

-

Roughing Toolpaths

-

Semi-Finishing Toolpaths

-

Finishing Toolpaths

-

Setting up the right Cutting parameters;

-

Speed

-

Feed

-

Depth of Cut.

-

Selection of Appropriate Toolpath Strategies for;

-

Turning

-

Facing

-

Grooving

-

Chamfering

-

Slotting

-

Post Processing the Toolpaths to get NC Code.

Register Now & Get Discount. Only Limited Seats Available. Grab The Offer Now.

Mastercam for 3 Axis Milling (VMC)

Design functionalities:

-

2D Design

-

3D Modelling functionalities

-

Process to import 3rd Party 3D CAD Models

-

Setting up the 2D/3D Model for Machining

-

Setting up Raw Material for the given Model

-

UCS

-

Selection of Right Cutting Tools for;

-

Roughing Toolpaths

-

Semi-Finishing Toolpaths

-

NonlFinishing Toolpaths

-

Setting up the right Cutting parameters;

-

Speed

-

Feed

-

Depth of Cut.

-

Selection of Appropriate Toolpath Strategies with respect to the Model Geometry.

-

Post Processing the Toolpaths to get NC Code for various VMC Machines/Controllers.

CAM Functionalities:

Mastercam for 5 Axis (Multi-axis – Machining)

Design functionalities:

-

2D Design

-

3D Modelling functionalities

-

Process to import 3rd Party CAD Models

-

CAM Functionalities:

-

Setting up Raw Material for the given Model

-

Setting up 5 Axis Environment.

-

Roughing Toolpaths

-

Semi-Finishing Toolpaths

-

Finishing Toolpaths

-

Setting up the right Cutting parameters;

-

Speed

-

Feed

-

Depth of Cut.

-

Selection of Appropriate 5 Axis Toolpath Strategies referring the complex models with undercuts, such as Blades, Impellers etc.

-

Post Processing the Toolpaths to get NC Codes.

Assignments, Case Studies & Projects

Trainer will follow through Tutorials and Projects of various type of components such as Mould, Dies and Engineering Components.Assignments will be given to complete.

Test Evaluation will be conducted by the Trainer at the end of the Training.

Certification IFS Academy Authorised Certificate of Completion.

Admission Procedure:

Course fees should be paid 100% advance. Last date for paying the fees is Friday, 1st May, 2020. Once fees is paid, you have to send us an email to training@ifsacademy.org with following details.

-

Name as per HSC

-

Mobile No

-

Email ID

-

Educational Qualification

-

Brief Work Experience

-

Specific Training outcome which you are looking at. (We will share this information with our Faculty in advance.)

You can also pay the fees online:

Account: IFS Academy

Bank and Branch: Axis Bank Ltd., Kothrud Branch, Pune-411038

Account Number: 104010200009058

Account Type: Current

Branch Code: 000104

IFSC Code: UTIB0000104

RTGS Code: Same as above

MICR Code: 411211004

Note: After a successful transaction, you are requested to send the following details to training@ifsacademy.org

Name of the Student:

Course Title:

Amount (Rs./-):

Transaction ID:

If you have any questions, please don’t hesitate to get in touch with us by emailing at training@ifsacademy.org or calling +91-7669293397